Dive Pigs recently attended Rod Gray's BBQ Competition Class and I can honestly say it was well worth it. He puts on a top notch class, is personable, keeps it real, and you won't go hungry.

He took the time to make sure he knew everyone, made sure we all had clear visibility of what he was doing, as well as made sure to triple review each and every technique with us. That being said, I will NOT be sharing what we learned in his class. If you want to know that, you will need to sign up for his class.

For more information on his class: Pellet Envy Classes

The experience left me with new friends, and built upon current skills and techniques... We covered Fires, Pits/Smokers, Chicken, Ribs, Pork Shoulders, and Brisket. Picking meats, weight, trimming, prepping, cooking, and boxing up for presentation. So much more ... was great, worth every penny!

As a bonus to the class, Rod had a pretty cool guest Pitmaster running his Jambo Pit for the weekend. Mr Jamie Geer himself. Not only did he run the pit, he also helped keep things picked up and running smooth. For more information on Jamie check out: Jambo Pits

Two of the most humble and real people I have ever met.

I won't leave Rod's wife out either, she was great. She did a presentation on how to box up your meats for presentation and she did a lot of work behind the scenes.

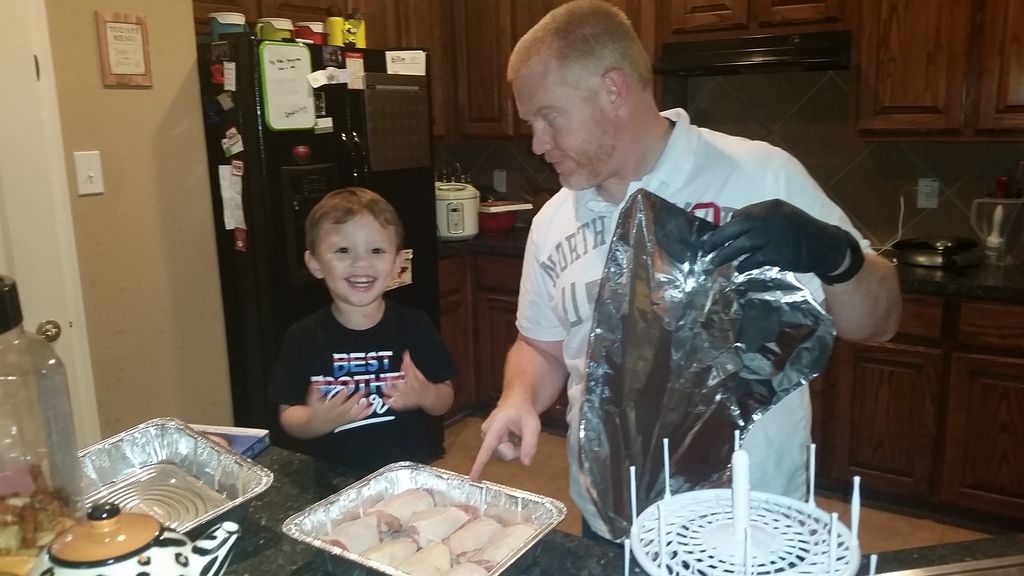

Came home with a nice bit of knowledge, a goodie bag, and a few new toys. Going to be practicing what I learned over the next couple weeks so I don't forget. Calvin (my 2 year old) decided to help me with the chicken. FYI - Heritage chicken thighs from Kroger will not be used again... they were not uniform in cut and just a pain to work with. Still, had a lot of fun with my son working on chicken.

Me, Jamie Geer, and Josh (in that order)

Josh and I at Rod's killer trailer (counters are 41" tall so no bending over while prepping) and a Jambo Pit on the back...

DivePigs BBQ

Tuesday, October 20, 2015

Sunday, June 7, 2015

North Texas BBQ Brethren BBQ Bash

Couple times a year, a bunch of people come together in celebration of killer BBQ, great friendships, and good clean fun. Every one of them enthusiastic about BBQ and passionate without a doubt. Last weekend they came together, rain didn't stop us. Of course some got there much earlier than others of us, but none the less "if you hold a BBQ gathering, they will come."

6am Saturday morning they fired up the pits ...

(Left is a Vault with I believe Gravity fed Coal / Chunk burner and Right is an Off-Set stick burner)

Even added a little protection against the rain ... sorry folks, no blankies here ...

6am Saturday morning they fired up the pits ...

Even added a little protection against the rain ... sorry folks, no blankies here ...

This is a pellet cooker - small and portable.

After getting brisket and larger pieces of meat on they started cooking Breakfast Fatties and Bacon Candie!

Bacon Candie in the making:

Breakfast Fattie (sausage rolled around eggs and potatoes)

This is Peep's Smoked Pepper Beef ... so freaking good ... nam nam nammy!

Dave and Chris both made Ribs ... Felt honored that Dave used my home made BBQ sauce to glaze his ribs:

Chris's Ribs:

Dave's Ribs:

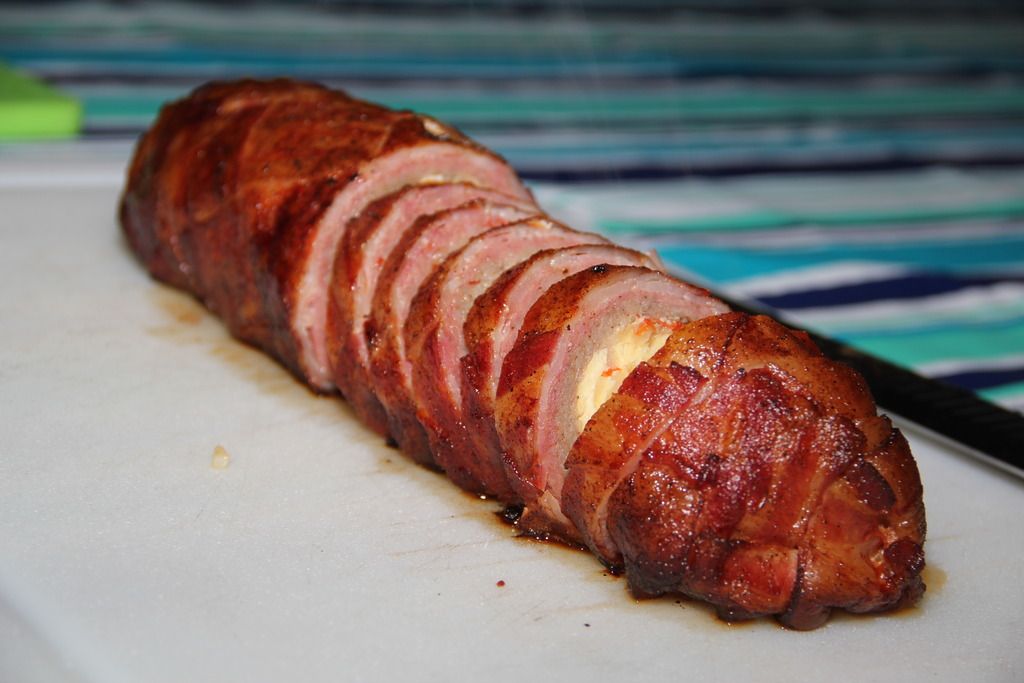

I did a Brisket and a Lechon Pork Belly (Filipino Style):

That's me in the camo hat cutting up the Brisket & Pork Belly Roll (Jeff, Chris, Russ, Peeps, then Dave - the far back is Peeps wife - guys please correct me if I got the names wrong - we all use "handles" on the forums)

Russ smoked Tri-Tip smoked to medium rare - juicy and good!!!

Charles made an amazing Brisket...

Peeps taught Dave the ways of Smoked - yes I said "SMOKED" Pecan Pie - SO GOOD!!!

Tradition dating all the way back to the first BBQ Brethren Bash get together (I believe early 80s) it has been a tradition to take a swig of Cabo ... several did, a handful of us don't drink so we cheered them on in support.

Was an awesome good time ... usually goes all day and is usually out at a lake where several will camp the night before. This time it wasn't possible as all the lakes/parks were closed due to heavy flooding... yes the great flood of Dallas that had many looking to build arcs. Huge shout out to Peeps for letting us crash his place and even bigger shout out to his wife for letting us.

I believe we are going to try and do a mini-bash get together sometime end of summer up near Lake Lavon for those interested.

I had a blast and love this group of guys!!! Smoke on my brothers, smoke on!

Wednesday, December 17, 2014

Smoked Bacon Dipped in Dark Chocolate

Every year in my family we try to make treats for friends and family. This year we are still making cookies but we are also doing something a little different.

SMOKED BACON DIPPED IN DARK CHOCOLATE SPRINKLED WITH COURSE SEA SALT!

Yes, I said that! And for you naysayers don't knock until you have tried it. It is quite good!

So for my first batch (test run) I took thick cut apple smoked bacon, smoked it on the pit at 350 for 25 minutes (next time I will smoke it at 325 for 25 minutes - little less dry crisp).

I brought the bacon in and let it cool and patted off the grease. Want to make sure you do this otherwise the grease will cause problems with the chocolate sticking.

While the bacon cooled I tempered/melted my chocolate.

This was done by bringing a pot of water to a boil, then reducing it to a slight simmer. Don't want to steam or boil your chocolate. Just need a little bit of heat to melt it. Also, avoid getting moisture in the chocolate as that will cause it to seize up. For this reason I use a bowl (aluminum or glass) that is much larger than the pot I use for boiling the water. I rest the bowl on the pot and have about 2" inches of clearance between the water and the bottom of the boil.

Put the bowl with chocolate in it over the simmering pot of water, use a plastic spatula (wooden or bamboo may cause the chocolate to seize) to stir, and after about 3 to 5 minutes you should have some shinny, smooth chocolate ready for coating the bacon.

Next batch I will be adding some bitter sweet bakers chocolate to the mix to help tone down the sweetness of the Hershey's Dark Chocolate.

Next dip the bacon and set on a rack to cool. Next time I will still use a cooling rack however I will put parchment paper down to help keep the bacon from sticking. (somehow I managed to NOT take a picture of the bacon cooling after being covered in chocolate). While the chocolate covered bacon is cooling, I lightly sprinkled with course ground sea salt the placed in the freezer for about 10 minutes.

Pulled them out of the freezer and dipped a 2nd time in the chocolate then put them back in the freezer for about 20 more minutes.

Learned a few things from this first test run...

SMOKED BACON DIPPED IN DARK CHOCOLATE SPRINKLED WITH COURSE SEA SALT!

Yes, I said that! And for you naysayers don't knock until you have tried it. It is quite good!

So for my first batch (test run) I took thick cut apple smoked bacon, smoked it on the pit at 350 for 25 minutes (next time I will smoke it at 325 for 25 minutes - little less dry crisp).

I brought the bacon in and let it cool and patted off the grease. Want to make sure you do this otherwise the grease will cause problems with the chocolate sticking.

While the bacon cooled I tempered/melted my chocolate.

This was done by bringing a pot of water to a boil, then reducing it to a slight simmer. Don't want to steam or boil your chocolate. Just need a little bit of heat to melt it. Also, avoid getting moisture in the chocolate as that will cause it to seize up. For this reason I use a bowl (aluminum or glass) that is much larger than the pot I use for boiling the water. I rest the bowl on the pot and have about 2" inches of clearance between the water and the bottom of the boil.

Put the bowl with chocolate in it over the simmering pot of water, use a plastic spatula (wooden or bamboo may cause the chocolate to seize) to stir, and after about 3 to 5 minutes you should have some shinny, smooth chocolate ready for coating the bacon.

Next batch I will be adding some bitter sweet bakers chocolate to the mix to help tone down the sweetness of the Hershey's Dark Chocolate.

Next dip the bacon and set on a rack to cool. Next time I will still use a cooling rack however I will put parchment paper down to help keep the bacon from sticking. (somehow I managed to NOT take a picture of the bacon cooling after being covered in chocolate). While the chocolate covered bacon is cooling, I lightly sprinkled with course ground sea salt the placed in the freezer for about 10 minutes.

Pulled them out of the freezer and dipped a 2nd time in the chocolate then put them back in the freezer for about 20 more minutes.

Learned a few things from this first test run...

- Less cook time on the bacon, thicker slice too

- Add Bitter Sweet Bakers Chocolate to the Hershey's Dark Chocolate to tone down the sweetness

- Use parchment paper to keep bacon from sticking to cooling rack after being covered in chocolate

- A little salt goes a very very long way!

Subscribe to:

Posts (Atom)